How Hemp/CBD Changed Medicine

Hemp/CBD & Your Health/Wellness

Here at Native Roots Hemp we spend most of our time helping guests better understand the endocannabinoid system and how our organically grown Wisconsin hemp helps the body remain in a more balanced state of being.

But sometimes, others can explain it even better! The article below talks about the Endocannabinoid System and it’s profound effects on the human body.

Hemraj, Dipak. “The Discovery of the Endocannabinoid System: How It’s Changed Medicine.” Cannabis Science, Leafwell.com, April 16, 2018, leafwell.com

It has been written or said in many places, but it is something that needs to be reiterated: had cannabis not become such a maligned plant, Raphael Mechoulam and his team would be awarded the Nobel Prize for the discovery of the endocannabinoid system (ECS). In fact, there are several researchers in the field of endocannoids and phytocannabinoids who would be worthy of such a prize. Thankfully, they have at least been awarded a multitude of other prizes, so we can be assured that there is at least some sense in the world. After all, “If viagra can win the Nobel Prize, why not cannabis?” (Please watch The Scientist to get this reference.)

These scientists have won so many prizes for a good reason; and that reason is because, in discovering the ECS, they’ve changed the way we look at the human body and medicine. Many used to believe that targeting one receptor using one highly purified drug was necessary, but the discovery of the ECS has changed their mind. Nowadays, much of the talk around developing safe pharmaceuticals concerns itself with the ECS and multi-modal treatments. In some cases, learning more about the medical properties of cannabis has made us better doctors.

Indeed, so significant is the discovery of cannabinoids and the endocannabinoid system, that it may help us answer one of life’s most fundamental questions: “How and why are we here?” This is because cannabinoids play a crucial role in the beginnings of life. To quote the Abstract from ‘The endocannabinoid-CB1 receptor system in pre- and postnatal life’:

“Recent research suggests that the endogenous cannabinoids (“endocannabinoids”) and their cannabinoid receptors have a major influence during pre- and postnatal development.

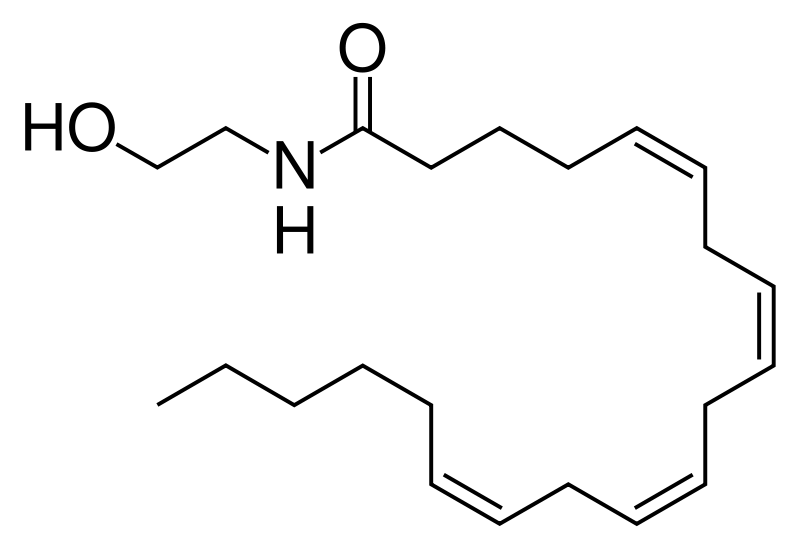

First, high levels of the endocannaboid anandamide and cannabinoid receptors are present in the preimplantation embryo and in the uterus, while a temporary reduction of anandamide levels is essential for embryonal implantation. In women accordingly, an inverse association has been reported between fatty acid amide hydrolase (the anandamide degrading enzyme) in human lymphocytes and miscarriage.

Second, CB1 receptors display a transient presence in white matter areas of the pre- and postnatal nervous system, suggesting a role for CB1 receptors in brain development.

Third, endocannabinoids have been detected in maternal milk and activation of CB1 receptors appears to be critical for milk sucking by newborn mice, apparently activating oral–motor musculature.

Fourth, anandamide has neuroprotectant properties in the developing postnatal brain. Finally, prenatal exposure to the active constituent of marihuana (Δ9-tetrahydrocannabinol) or to anandamide affects prefrontal cortical functions, memory and motor and addictive behaviors, suggesting a role for the endocannabinoid CB1 receptor system in the brain structures which control these functions.

Further observations suggest that children may be less prone to psychoactive side effects of Δ9-tetrahydrocannabinol or endocannabinoids than adults. The medical implications of these novel developments are far reaching and suggest a promising future for cannabinoids in pediatric medicine for conditions including “non-organic failure-to-thrive” and cystic fibrosis.”

To break that down for you:

- The body’s own version of THC, anandamide, is necessary for human life to happen in the first instance.

- Cannabinoid receptors are necessary for brain development.

- Endocannabinoids have been discovered in the maternal milk of mice, and there is no reason to believe that other mammals’ milk is not the same.

- Anandamide protects the brains of newborns.

- Prenatal exposure to THC or anandamide affects memory, motor and addictive behaviors, and prefrontal cortical functions.

Some theorize that children may actually be less prone to the psychoactive effects of THC! Though there is no definitive evidence behind this, the logic seems to be that, due to the high amounts of anandamide in children, THC may not affect them in the same way it affects adults! This is one more reason given as to why cannabinoids may be an excellent treatment method for children.

However, we are sceptical of this claim, as cannabinoids play a massive role in the development of the brain during childhood and teenage years, and introducing phytocannabinoids without medical supervision during such a sensitive period may cause potential health problems, in particular mental health. There is significant research suggesting that those aged under 25 are actually more sensitive to THC, as their brains are developing. As for CBD, as it is a cannabinoid that does not have any affinity for CB1 or CB2 receptors, it is unlikely to have the effects THC has. Still, we do not know for sure precisely what sort of effect has long-term. CBD still has a physiological effect, after all.

Those who need cannabinoids for a particular health condition, they are still a potentially valid treatment regardless of age. We must also ask ourselves, “Why don’t we treat many other drugs and medications the same way and see what effect they have on the brains of children?” After all, many children are prescribed much harsher drugs than THC when they suffer from serious conditions.

Now, we don’t know about you, but this sort of thing gets us excited, and we’d be surprised if anyone doesn’t get as excited as we are about such research. Cannabinoids being one of the reasons why life exists? This is the sort of talk that belongs in stoner circles. Yet at least one of those circles must have the spirit of Carl Sagan and other prominent now sadly-passed scientists possessing them, as that talk may just well be true!

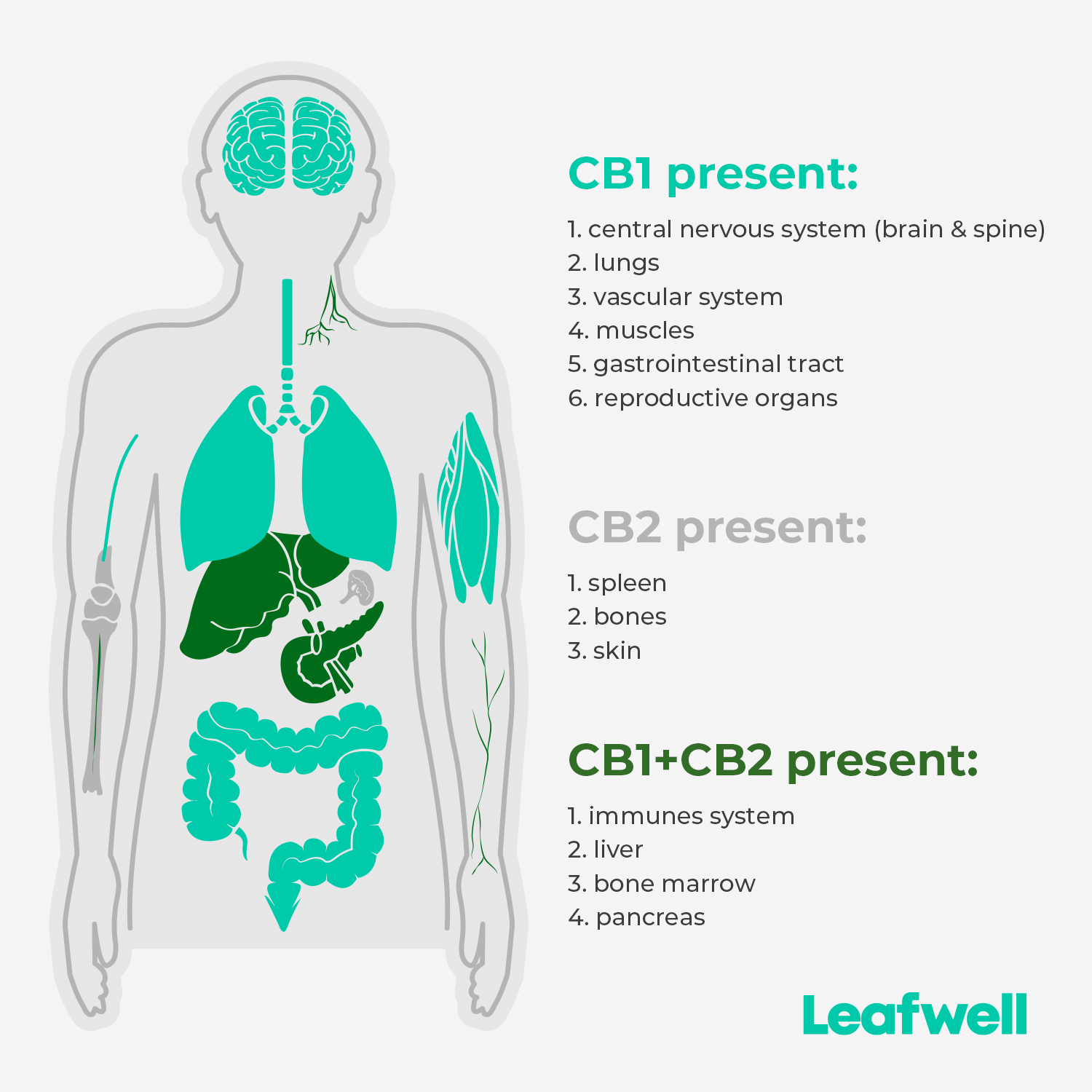

Now, not only do cannabinoids seem to have a massive role to play in the beginnings of life, but it may also perform an immensely important part in the continuation of it as well. Cannabinoids are intimately involved in homeostasis – the “checks and balances” that keep the body and its physiological processes in equilibrium. Anandamide is hugely important for maintaining immunological health in the gut. Learning about endocannabinoids and endocannabinoid has given us a greater understanding of immune regulation, and the advances made in cannabinoid pharmacology have given us a whole new range of therapeutic targets. In fact, the ECS has potentially given us an entirely new branch of therapies. The reason why cannabis may be useful for so many conditions is because an “out-of-tune” ECS is implicated in many disease states.

That cannabinoids may make up the constituents of life is nothing short of an outstanding discovery. It is almost surprising that we have only just discovered it just over two-and-a-half decades ago. The ECS is so complex that we have barely just begun to scratch the surface on what it does and how we can modulate it. There is still lots more to be done, There is actually lots to be discussed here, and in some ways the way we treat the cannabis plant has asked a some questions that shake some of the philosophical underpinnings of medicine. “How do we ensure the cure isn’t as bad and dangerous as the disease we’re trying to treat?” “Why do we prescribe things that are much worse than cannabis, especially when sometimes the evidence is shaky at best?” “Are there ways we can treat a condition without the need for invasive surgery and/or harsh pharmaceutical drugs?” Who knows? One day, many of the medicines at your local pharmacist may be cannabinoid- and/or terpenoid- based!